Bacteria found in one of the compartments of a cow’s stomach can break down plastic, research suggests.

Since the 1950s, more than 8bn tonnes of plastic have been produced – equivalent in weight to 1 billion elephants – driven predominantly by packaging, single-use containers, wrapping and bottles. As a result, plastic pollution is all-pervasive, in the water and in the air, with people unwittingly consuming and breathing microplastic particles. In recent years, researchers have been working on harnessing the ability of tiny microscopic bugs to break down the stubborn material.

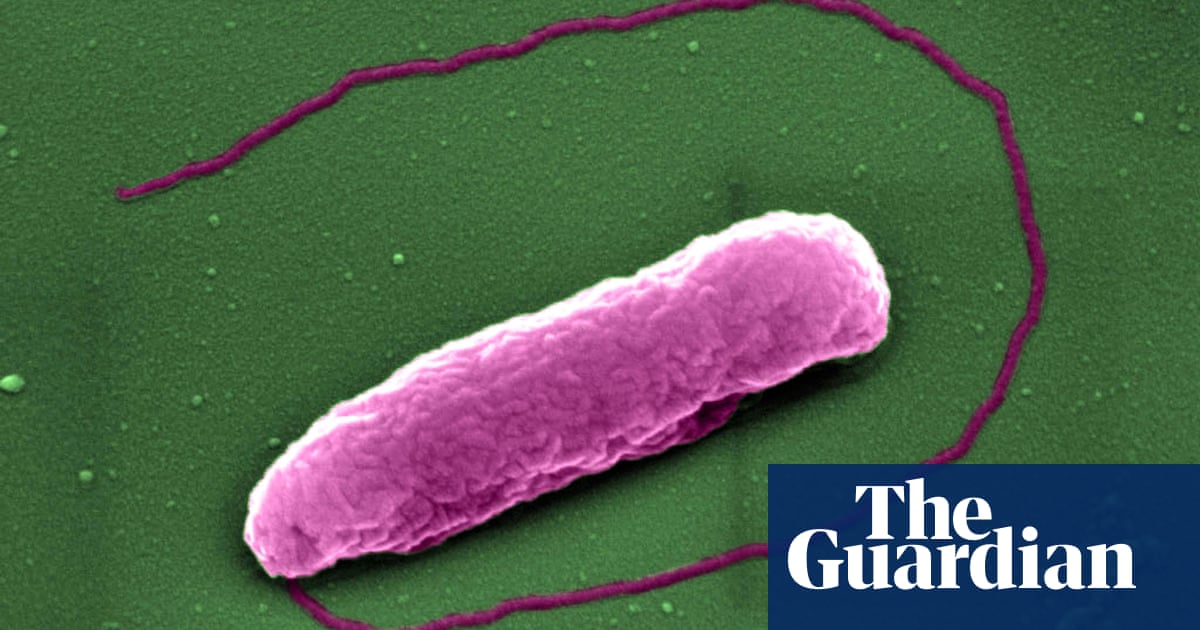

There are existing microbes that are able to degrade natural polyester, found for example in the peels of tomatoes or apples. Given that cow diets contain these natural polyesters, scientists suspected the bovine stomach would contain a cornucopia of microbes to degrade all the plant material.

To test that theory, Dr Doris Ribitsch, of the University of Natural Resources and Life Sciences in Vienna, and her colleagues procured liquid from the rumen, a compartment of a cow’s stomach, from a slaughterhouse in Austria. One cow typically produces a rumen volume of about 100 litres, noted Ribitsch. “You can imagine the huge amount of rumen liquid accumulating in slaughterhouses every day – and it’s only waste.”

That liquid was incubated with the three types of polyesters – PET (a synthetic polymer commonly used in textiles and packaging); PBAT (biodegradable plastic often used in compostable plastic bags); and PEF (a biobased material made from renewable resources). Each plastic was tested in both film and powder form.

The results showed all three plastics could be broken down by the micro-organisms from cow stomachs in the lab setting, with the plastic powders breaking down quicker than plastic film. The next steps, she said, were to identify those microbes crucial to plastic degradation from the thousands present in the rumen, and then the enzymes produced by them. Once the enzymes have been identified, they can be produced and applied in recycling plants.

For now, plastic waste is mostly burned. To a lesser extent, it is melted for use in other products, but beyond a point it becomes damaged and can no longer be used again. Another method is chemical recycling – turning plastic waste back into base chemicals – but that is not an environmentally friendly process. Using enzymes is billed as a form of green chemical recycling.

Other researchers are further along in their quest to developing and scaling such enzymes. In September a super-enzyme was engineered by linking two separate enzymes, both of which were found in the plastic-eating bug discovered at a Japanese waste site in 2016.

The researchers revealed an engineered version of the first enzyme in 2018, which started breaking down the plastic in a few days. But the super-enzyme gets to work six times faster. Earlier in April, the French company Carbios revealed a different enzyme, originally discovered in a compost heap of leaves, that degrades 90% of plastic bottles within 10 hours.

In the rumen liquid, it appears there is not just one type of enzyme present, but rather different enzymes working together to achieve degradation, the authors suggested in the journal Frontiers in Bioengineering and Biotechnology.

Carbios was working on scaling up its technology, noted Ribitsch. “But of course, it’s always good to have even better enzymes that are maybe recycling other polymers, not only PET, for example … so it can be seen as a general recycling material.”