Rare earth elements from ore are vital for modern life, as they are involved in many industries. But refining them after mining is costly, and harms the environment, so it’s avoided by most countries seeking to address pollution problems.

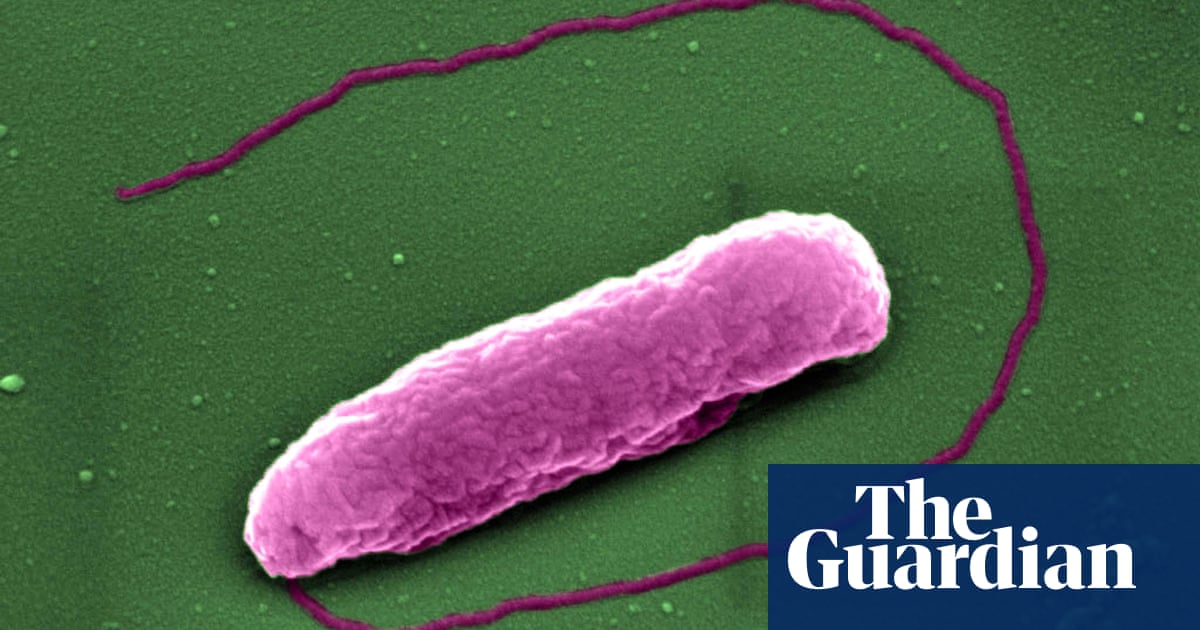

A new study describes a proof of principle for engineering a bacterium, Gluconobacter oxydans, that takes a big first step towards meeting skyrocketing rare earth element demand in a way that matches the cost and efficiency to meet US environmental standards.

The elements -- of which there are 15 in the periodic table -- are necessary for everything from computers, cell phones, screens, microphones, wind turbines, electric vehicles and conductors to radars, sonars, LED lights and rechargeable batteries.

While the US once refined its own rare earth elements, that production stopped more than five decades ago. Now, refinement of these elements takes place almost entirely in other countries, particularly China.

To meet US annual needs for rare earth elements, roughly 71.5 million tons of raw ore would be required to extract 10,000 kilograms of elements.

Current methods rely on dissolving rock with hot sulphuric acid, followed by using organic solvents to separate very similar individual elements from each other in a solution, a process in which bacteria can contribute in an eco-friendly way.

G. oxydans is known for making an acid called biolixiviant that dissolves rock; the bacteria use the acid to pull phosphates from rare earth elements. The researchers have begun to manipulate G. oxydans genes, so it extracts the elements more efficiently.

To do so, the researchers used a technology called Knockout Sudoku, that allowed them to disable the 2,733 genes in G. oxydans’ genome, so they could identify which genes play roles in getting elements out of rock.

“I am incredibly optimistic. We have a process here that is going to be more efficient than anything that was done before,” said Esteban Gazel, associate professor of earth and atmospheric sciences at Cornell in a report.

The rare Earth elements used the most in industries are Lanthanum, Cerium, Neodymium, and Yttrium.

In former research, a team of researchers from the IMC Krems in cooperation with the Czech Academy of Sciences, Danube University Krems and Karl Landsteiner Privatuniversität, found a method to extract these rare elements from electronics using bacteria as well.

This method relies on dissolving electronic waste with nitric acid, followed by using an organic solvent and living organisms such as fungus, algae, and bacteria including Bacillus subtilis and Escherichia coli, so the scientists can extract the rare earth elements from these organisms.